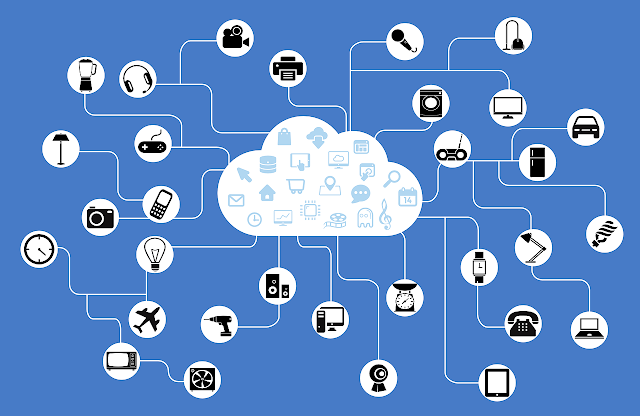

There are various characteristics which need to be met in order for

these machines to be suitable and to be fully and successfully

implemented into real time systems. These characteristics are as

follows: size and weight, power and cooling, operating environment, cost

and performance.

Computing Performance. Computing performance in a real time embedded control environment is not simply defined. Although raw computational performance is important, there are other factors which influence the system. An additional desirable feat is a fantastic execution in programs that are filled with procedure calls reducing program memory size.

Size and Weight

It has been observed that stack computers are very simple in regards to processor complexity. However, it is the overall system complexity that determines overall system size and weight. The solution to overcoming the size and weight issue is to keep component count small. That is why stack machines are less complex than other machines and are also more reliable.Power and Cooling

If the processor is complex, it can affect the amount of power it needs. That amount of power is related to how many transistors there are in a processor and how many pins are on the processor chip. Moreover, processors that need a lot of power-consuming high-speed memory devices can also be burdensome regarding power. Of course, power consumption directly affects cooling requirements, since all power used by a computer is eventually transmuted into heat. The cooler operation of processor components can reduce the number of component failures, thus improving reliability.Operating Environment

Embedded processing systems are well known for extreme operating conditions. The processing system must deal with heat and cold, vibration, shock, and even radiation. Also, in remotely installed applications, the system must be able to survive without field service technicians to make repairs. The general rule to avoiding problems caused by operating environments is to keep the component count and a number of pins minuscule. Stack machines, with their low system complexity and high levels of integration, do well under these conditions.Cost

Since the cost of a chip is related to the number of transistors and to the number of pins on the chip, low complexity stack processors are basically low in cost.Computing Performance. Computing performance in a real time embedded control environment is not simply defined. Although raw computational performance is important, there are other factors which influence the system. An additional desirable feat is a fantastic execution in programs that are filled with procedure calls reducing program memory size.